Renishaw’s first product, the touch-trigger probe was invented 50 years ago

Renishaw’s first product, the touch-trigger probe, was invented 50 years ago to solve a specific inspection requirement in manufacturing. Since then, our innovative CMM products have significantly reduced the time to produce and inspect components for manufacturers in the most demanding industries. Read more [Picture source: Renishaw on linkedin.com]

Waarom industriële robots nauwkeuriger maken

Ten eerste zorgt nauwkeurigheid ervoor dat de robot taken met precisie uitvoert, wat resulteert in producten van hoge kwaliteit. Dit is vooral belangrijk in industrieën zoals de auto-industrie en elektronica, waar zelfs kleine afwijkingen kunnen leiden tot defecte onderdelen of slecht functionerende producten. Lees verder [Bron foto: Renishaw Benelux B.V. op LinkedIn.com]

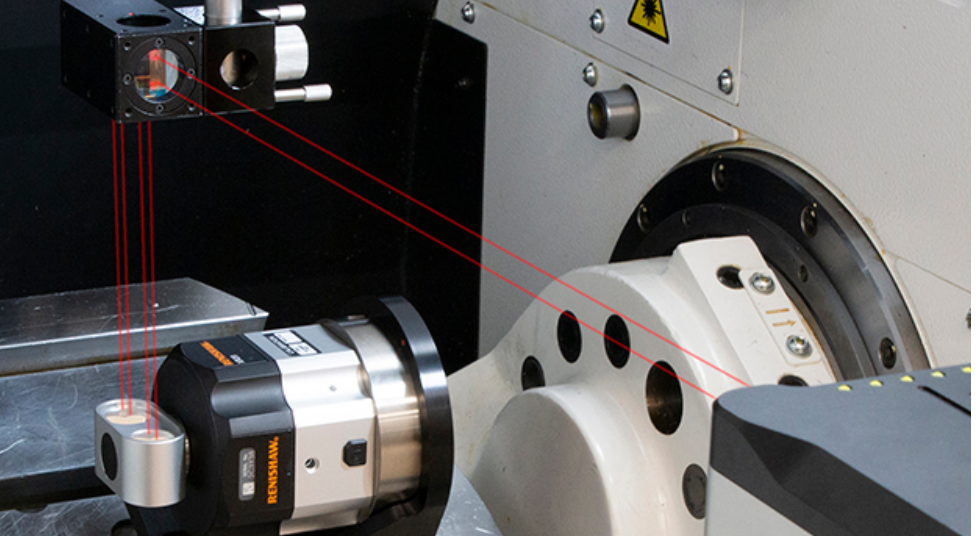

Non-contact tool setter – How to set up a tool profile check on the NC4 | Renishaw

In this tool setting how-to video, Dan and Iain explain how to check a tool’s profile using NC4+ Blue tool setter. They discuss why you would do a tool profile…

The RenAM 500 Flex is a metal additive manufacturing (AM) system, ideal for R&D applications

Equipped with an open-loop powder system that allows for quick and easy powder swapping, the RenAM 500 Flex is optimised for research and development applications. This system is highly efficient in speeding up the qualification of material properties, part design, and process parameters. Read more and watch the video

Wist je dit? Wij bieden oplossingen voor neurochirurgen

We gebruiken onze expertise op het gebied van precisie-engineering om de toekomst van stereotactische neurochirurgie en gerichte medicijnentoediening een stap verder te brengen in de behandeling van patiënten met uiteenlopende neurologische aandoeningen. Lees verder [Bron foto: Renishaw Benelux B.V. op linkedin.com]

Introducing the CENTRUM™ CSF40 self-centring scale disc with two fixing options – bolts or a clamp

For use with the ATOM DX™ encoder series, CENTRUM™ CSF40 scale discs are quick and easy to install ‘right first time’, due to their innovative mounting features that automatically centre the…

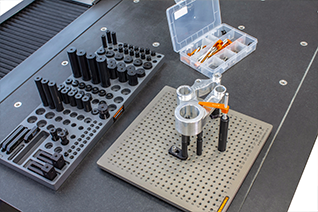

Metrology fixtures for CMM and gauging

Metrology fixtures for co-ordinate measuring machines (CMMs) and Equator™ gauging can improve the throughput, reproducibility and accuracy of your inspection process by providing quick and repeatable fixturing set-ups for your components. Read more

50 jaar innovatie – Gemotoriseerde Renishaw meetkoppen

De PH9 gemotoriseerde meetkop, die Renishaw in 1980 introduceerde, bracht een kentering teweeg op de CMM-markt door een automatische en herhaalbare methode te bieden om de tasterhoek te veranderen. Hij bood 720 verschillende posities en hoefde voor elke positie maar één keer gekalibreerd te worden, waardoor de verwerkingscapaciteit van CMM’s enorm verbeterde.

What is an XR20 rotary axis calibrator?

The XR20 rotary axis calibrator works in conjunction with XL-80 and XM-60 laser systems providing highly accurate, repeatable rotary axis calibration for stages, jigs and machine tools. It consists of an integrated angular retroreflector mounted on a precision servo-controlled axis. The angular…

Gegevens zijn cruciaal voor beheersing van productieprocessen

Veel klanten met een Equator™ meetsysteem profiteren van een geïntegreerde oplossing voor bewerkingsmachines met Renishaws Intelligent Process Control (IPC) software. Lees verder